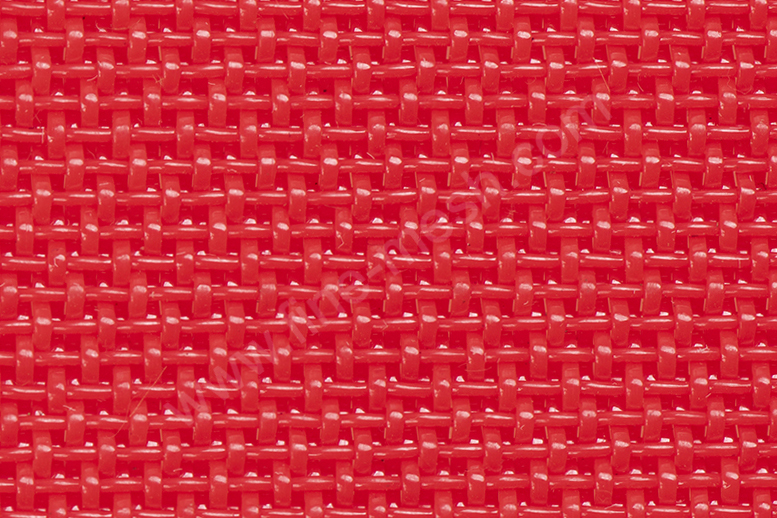

Flat Yarn Woven Dryer Fabric

The dryer fabric is mainly used in the dryer section, and its function is to tightly wrap or carry wet paper web for transmission; The paper has good surface smoothness through smooth and fine mesh design; Match the moisture evaporation requirements of the web at different positions through appropriate permeability design; At the same time, it can meet the operation test of dryer section under such harsh conditions as high temperature, high humidity, extreme acidity and alkalinity.

Description

The dryer fabric is mainly used in the dryer section, and its function is to tightly wrap or carry wet paper web for transmission; The paper has good surface smoothness through smooth and fine mesh design; Match the moisture evaporation requirements of the web at different positions through appropriate permeability design; At the same time, it can meet the operation test of dryer section under such harsh conditions as high temperature, high humidity, extreme acidity and alkalinity.

It also called dryer screen ,dryer mesh, dryer canvas or dryer belt.

It mainly have four type such as flat yarn woven dryer fabric, round yarn woven dryer fabric, round yarn spiral dryer fabric, flat yarn spiral dryer fabric.

Advantages

The flat yarn woven dryer fabric for paper making is woven from warp and weft. The utility model is characterized in that the warp and weft of the hydrolysis resistant polyester material are used. The warp includes the top warp and the bottom warp. The two warp lines form a group, and they are woven by two groups of four warp lines and two weft lines of different diameters. The warp is flat and the weft is round.

The use of flat wire in warp can increase the contact area between the wire surface and the paper, thus promoting the heat transfer between the cylinder and the paper surface. Additionally, the flat wire dry mesh is thin. When water vapor passes through the mesh, the chance of condensation of water vapor is reduced, which can effectively improve the drying efficiency. The flat wire dryer fabric surface is smooth, and the mesh mark produced by the flat wire mesh is lighter than that of the round wire mesh during the paper drying process. Because the flat wire dryer fabric is made of anti-hydrolysis monofilament, the service life of the dryer fabric is effectively extended, and the economic benefits are improved.

PPS Yarn

PPS yarn is superior to polyester monofilament in high temperature resistance, wear resistance, aging resistance, and other aspects. Fine Mesh’s special design uses PPS monofilament to weave the edge of paper making dryer fabric, that is, it is directly attached to the edge of the fabric on the dryer cylinder. Compared to the dryer fabric woven entirely with PPS monofilament, it not only saves costs but also has a service life twice as long as polyester paper making dryer fabric.

Features

- The mesh is thick, flat, good dimensional stability and long service life.

- Good interface structure improves interface smoothness.

- The ring with larger diameter increases the strength of the interface.

- Permeability:It can avoid wasting heat and improve drying efficiency for it’s permeability.

- Chemical resistance:It can resist all most of chemical medicines.

- High temperature resistance.