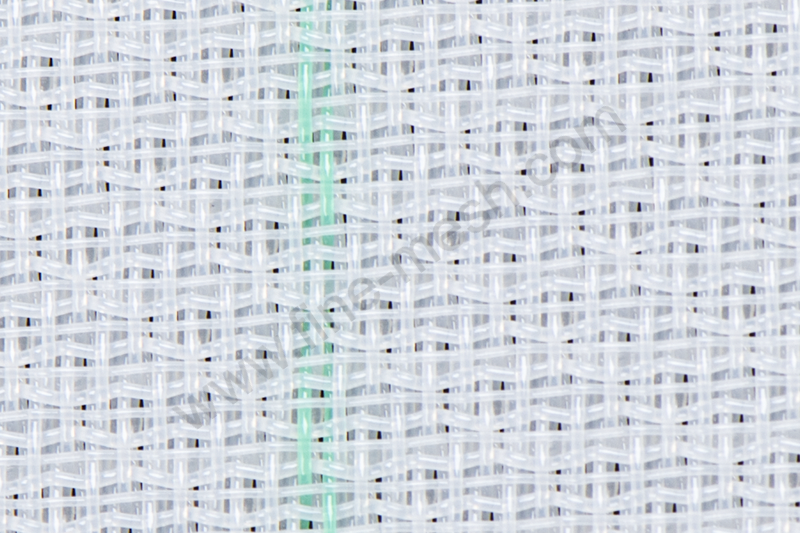

Double Layer Forming Fabric

Double layer forming fabric usually means that the weft yarn has a double-layer structure. Compared to a single layer forming fabric, a double layer of warp and weft has a higher density, strong stability, but is less stretchable.

Description

Double layer forming fabric usually means that the weft yarn has a double-layer structure. Compared with single layer forming fabric, double layer warp and weft have higher density, strong stability, but less stretchable.

Structure

The structure of Fine Mesh Factory double-layer forming fabrics is generally a double-layer weft structure; the manufacturing method is the seamed (H) type. Compared to single-layer, densities of warp and weft are higher. Double-layer is more dimensionally stable but less stretchable. Diameters and material types of sheet-side and machine-side wefts can be selected independently, enabling improvements in wire mark, two-sidedness, flatness, and fabric life. Thanks to the large three-dimensional space (flat spaces are almost zero), our double-layer also provides excellent drainage property. Drainage force does not directly affect the paper layer, which helps improve retention and prevents lint.

Advantages

- Fine papermaking surface on top giving high fiber support.

- Improved formation and retention.

- Improved fabric life.

- Enhanced dimensional stability and stretching resistance.

Application

The double layer has higher warp and weft density making it more stable than the single layer. That said the double layer is less stretchable. It suitable for paperboard,newsprint,writing paper,tissue paper,printing paper,kraft paper,etc.