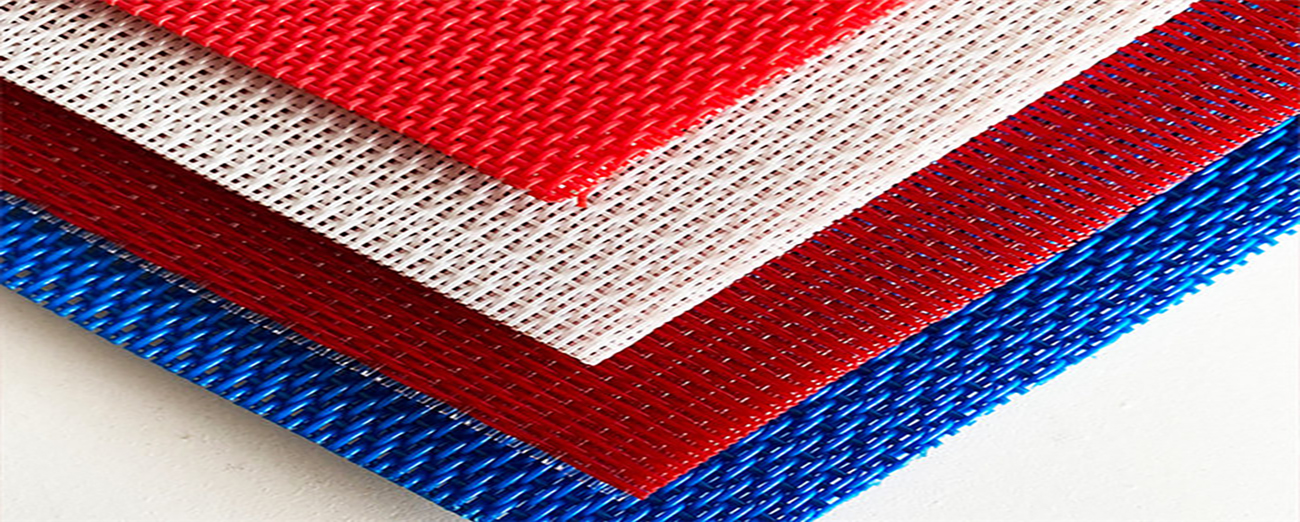

Characteristics of Paper Machine Dryer Fabrics:

High strength, good toughness, wear resistance, corrosion resistance, and stable dimensions.

Smooth surface and good air permeability.

Lightweight and convenient transportation.

Application of Paper Machine Dryer Fabrics:

The polyester dryer fabric is made of polyester monofilament woven material, which is mainly used for drying paper products on the paper machine.

Polyester dryer fabric can be divided into ordinary dry net and pressurized dry net according to the organization. According to the seam method, it is divided into two types: end seam and loop seam.

Paper Machine Dryer Fabrics maintenance, cleaning and precautions:

There are two bonding methods on both sides of the dry net: glue bonding and hot melt bonding. In the course of use, if divergence occurs, the loose end of the line can be cut off and then powered on. The soldering iron can be fused.

The mesh can be stitched when it is stitched due to strong wounds or other causes of small holes, local damage, etc.

During use, if small holes due to wrinkles or partial breakage occur, stitches can be sewn with thread.

When shutting down due to power failure or other reasons, please immediately close the gas valve and loosen the net to prevent local deformation and aging.

When there is local grease on the surface of the mesh, it can be scrubbed with gasoline or detergent, and then rinsed with water.

During transportation, storage, installation, maintenance and operation, keep away from open flames and high temperatures to prevent the dry net from burning and aging, and to prevent friction with sharp objects, so as not to scratch the net and reduce maintenance life.

Leave A Comment